Automotive measuring tool for verifying bearing clearances, introduced as Powerbuilt Plastic Gauge. Engine builders and mechanics gain confidence during assembly with a simple torque-and-compare checking method. Is this a workshop staple worth adding to routine rebuild checks?

⚡ At a Glance

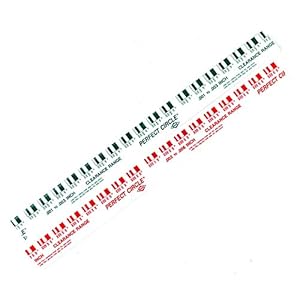

- • Measurement Range: Includes green tape (.001" - .003") and red tape (.002" - .006")

- • Best for: Engine builders and mechanics verifying oil clearance

- • Not ideal for: Situations requiring digital readouts or sub-micron micrometre precision

Dual colour-coded tape strips cover very small oil clearances. Torque the assembly to spec and compare the tape width to the printed scale for a clearance reading.

Accurate bearing clearance checks - with dual-range tape strips

Colour-coded plastic strips capture the maximum clearance width when placed between bearing and journal and the assembly is torqued to specification. Two tape ranges cover small oil clearances, allowing direct comparison against a printed scale.

Provides repeatable clearance readings without complex measuring instruments. Results help confirm correct oil clearance during engine assembly.

Faster, repeatable workflow - thanks to the torque-and-compare method

A strip is positioned between bearing and journal, the part is torqued to spec, and the strip is removed and measured against the scale. The simple sequence reduces steps compared with multiple micrometre measurements.

Speeds up checks during rebuilds, letting technicians complete clearances in minutes. Repeatable method reduces the chance of assembly errors.

✨ The 4 Key Reasons for Powerbuilt Plastic Gauge

- Made in the USA - Reassures users with domestic manufacturing and quality control

- Simple torque-based technique - Complete clearance checks during assembly in minutes

- Plastic construction - Lightweight and easy to handle in tight engine bays

- Workshop-ready tool - Requires no power source or specialist calibration

📋 Technical Details at a Glance

- Category: Automotive Parts and Accessories

- Brand: Powerbuilt

- Model: 648441

- Product ID: B002INTX3C

- Material: Plastic tape and strips

❓ Frequently Asked Questions

Q: What measurement ranges are covered by the gauge?

A: The kit includes green tape covering .001" - .003" and red tape covering .002" - .006" for small oil clearance checks.

Q: How is the gauge used to measure clearance?

A: Place a strip between the bearing and journal, torque the assembly to the specified value, remove the strip and compare the width to the printed scale.

Q: Which bearings can be checked with the gauge?

A: Suitable for verifying oil clearance on crankshaft bearings, rod bearings and main bearings.

🏆 Our Verdict

The Powerbuilt Plastic Gauge suits engine builders and mechanics who need a quick, manual method to verify oil clearances. Colour-coded tape strips and a torque-and-compare workflow make accurate checks straightforward. As a simple, workshop-ready tool made in the USA, it delivers long-term value by reducing rework and assembly guesswork.